▌ Aluminum Forging

『Aluminum Forging Theory&Application』

Aluminum Forging Theory&Application

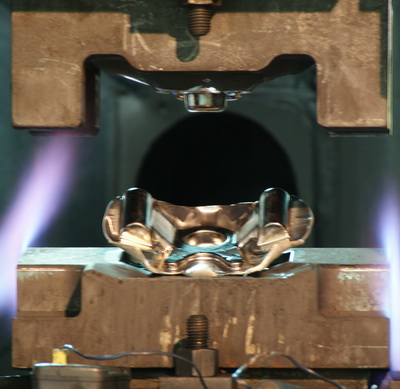

Forging is a manufacturing process that preheating of the material to be squeezed into the mold under great pressure.

In the forging process, the aluminum bar or ingot must be preheated to assigned temperature(≒ 500°C )by circulation furnace before processing, and then place into the mold via high pressure press by forger. Thus, this process is just the initial processing and must have post-processing (such as heat treatment, CNC machining, sandblasting, etc.) to reach the customer demands.

Aluminum forging applications for automotive industry includes suspension system, crankshafts, axle, piston, and transmission system. For motorcycle and motor scooter industry such as break lever, pulley, caliper, and other exterior parts etc.

Besides the common material that we can offer, HYS has developed a new material named AH168 which has better heat & wear-resistance, and smaller coefficient of expansion. Welcome to contact us and know about AH168 more